Description

Manufacturer

Product Tags

Designed to make a

difference

ZF Race Engineering's SACHS motorsport clutches have stood for top-tier quality in international racing for decades. The ambition: continuous improvement and the drive to keep pushing the limits. From the lightest clutch used in Formula 1 to proven twin-plate and multi-plate systems in WRC, DTM, NASCAR, Le Mans and the Dakar Rally - ZF Motorsport technology is a core component of many winning cars worldwide.

SACHS Racing Clutch

RCS 4/140 S2.6

Sintered metallic 2.6 mm, rigid design

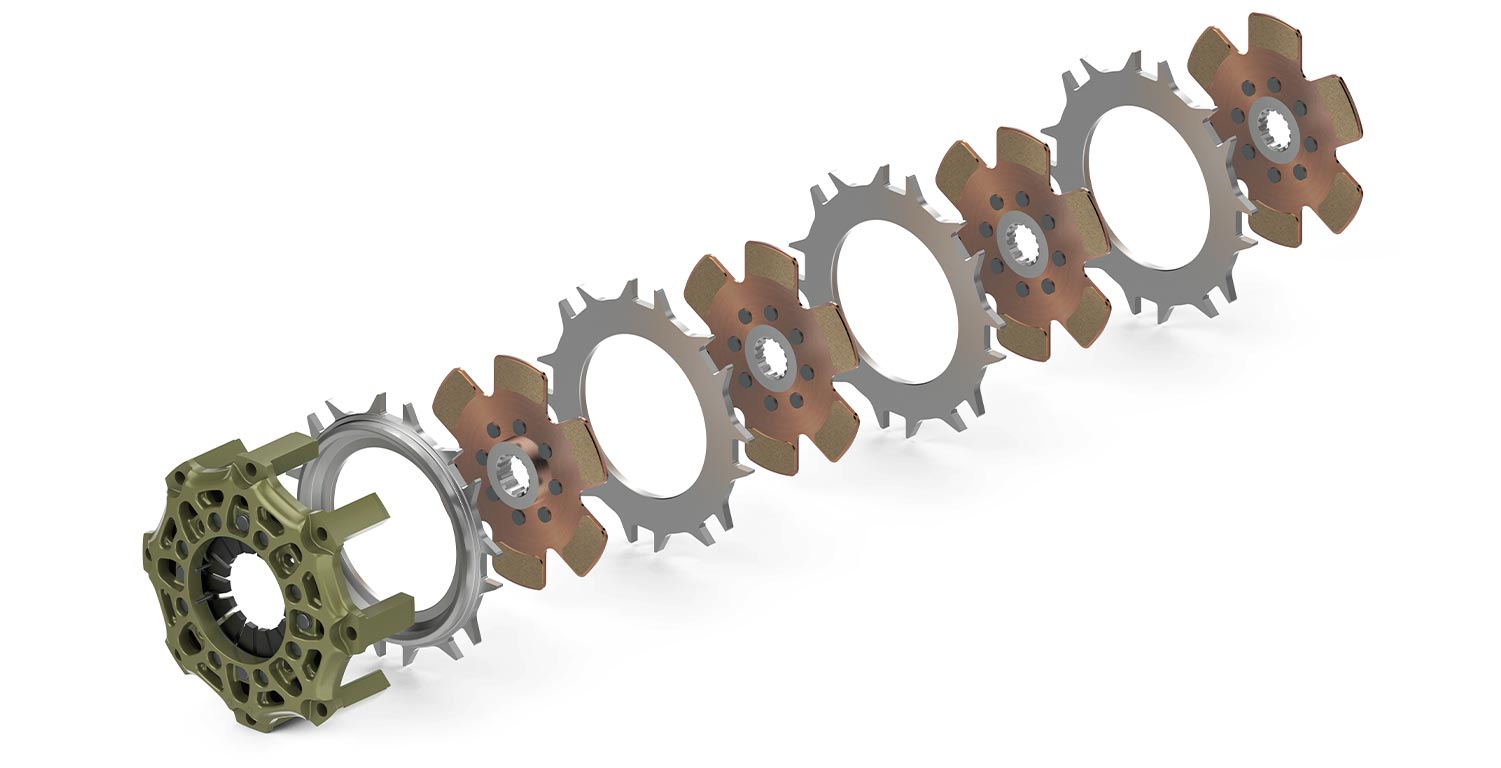

Compact and extremely free-revving: the four-plate SACHS RCS 4/140 S2.6 uses the small 140 mm friction diameter to achieve a very low moment of inertia for the clutch unit and short shift windows. The engine builds revs noticeably more freely, rotating masses in the drivetrain are reduced, and load changes translate much faster. The multi-plate design spreads friction work and heat across multiple contact surfaces, increases transferable torque capacity, and enables this at minimal overall height. Ideal for formula series, prototypes, and sprint-oriented GT setups with tight installation space.

The 2.6 mm sintered metallic lining (sintered to the carrier plate) prioritizes low rotating mass and fast heat dissipation. The result: very direct response, quick rev matching, and consistent pedal feel — especially valuable in sequences with frequent shifts. Versus 5.2 mm sinter pads, 2.6 mm brings less thermal inertia and thus a more agile character; 3.4 mm is a compromise in between, adding a bit more heat buffer at slightly higher mass.

This configuration transmits up to 1,910 Nm maximum engine torque. The forged aluminum clutch cover (housing) combines high stiffness with low weight and supports heat dissipation; pressure and intermediate plates in high-strength steel ensure launch and endurance strength — engineered for repeatable performance in demanding racing use.

Advantages

Light

low clutch height

Low mass and inertia

Less Mass

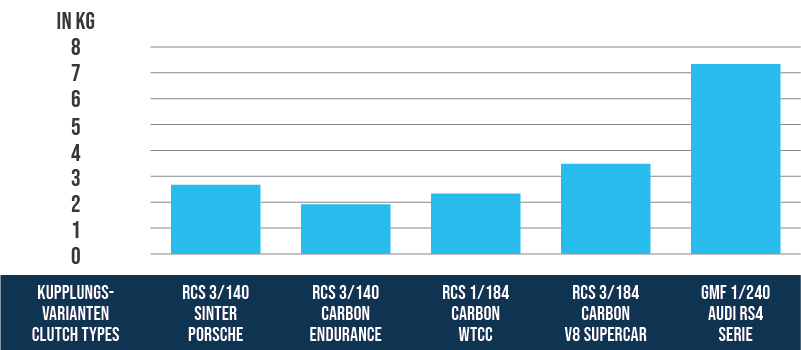

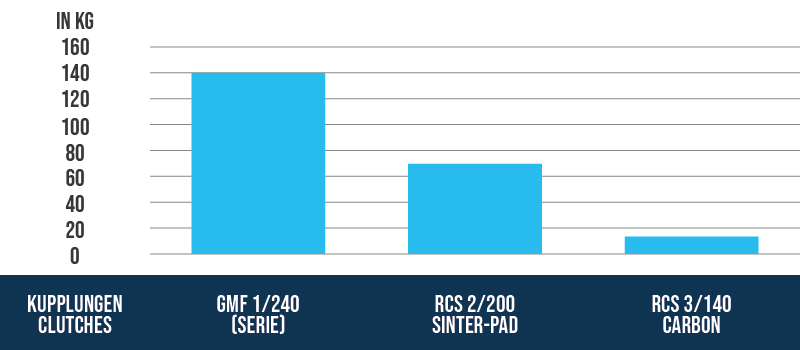

One of the greatest strengths of the RCS sintered clutch is its low mass and the associated low mass inertia.

The SACHS RCS clutches have been designed for racing with the objective that torque is transmitted rapidly and directly from the engine to the gearbox.

Reducing the weight of the crankshaft drive to lower the moment of inertia will considerably increase vehicle acceleration performance in the lower gears.

Faster Acceleration

If the clutch itself has a moment of inertia (MoI) of 0.061 kgm2, the MoI on the drive wheel will be 180 times higher (in first gear) for a reduction in transmission of 13.4:1 (13.42). If we convert this value into vehicle mass, we arrive around 145 kg of additional weight to be accelerated in first gear.

As a result of the low moment of inertia of the SACHS RCS clutch, shifting times are considerably reduced and the vehicle accelerates much faster.

Technology

Technical data RCS 4/140:

- maximum engine torque [Nm]: 1,910

- release diameter [mm]: 49 / 38

- release force [N]: 4,900 / 4,200 (∅ 38)

- release travel [mm]: 4.0 +0.5 / 4.5 +0.5 (∅ 38)

- mass (weight) [kg]: 3.52 / 3.57 (∅ 38)

- moment of inertia [kgm2]: 0.011207 / 0.011214

Clutch cover (housing)

The RCS 140 housing is made of high-strength forged aluminum and engineered for maximum stiffness at minimum weight. Its geometry supports efficient heat dissipation and stabilizes the temperature window of the clutch pack. A wear-resistant hard coating reduces friction and fit wear, increasing service life.

Friction lining — sintered metallic

Sintered metallic linings offer high temperature resistance, very good thermal conductivity, and fade resistance — ideal for dry high-load applications. The 2.6 mm thickness prioritizes lowest inertia and quick response; 3.4 mm adds heat buffer at slightly higher mass, while 5.2 mm maximizes reserves and durability but responds more slowly.

SACHS RCS hub

The RCS 4/140 S2.6 racing clutch is available with different hub spline profiles tailored exactly to the respective gearbox input shaft. This guarantees high fit accuracy, reliable power transfer, and maximum motorsport durability. Hub lengths (short, medium, long) allow optimal packaging and correct actuation. The modular RCS 140 system enables individual tuning for performance, thermal robustness, and service life. Standard configuration of the RCS 4/140 clutch (unless otherwise specified): hub length short–short–short–short.

Scope of supply

RCS 140 clutch cover (HA140), aluminum

1× RCS 140 pressure plate (PP140), steel

3× RCS 140 intermediate plate (IP140), steel

4× RCS 140 clutch disc, sintered metallic 2.6

Hub length: short–short–short–short

Quality Made in Germany

ZF Race Engineering has been among the technology leaders in motorsport for years. The combined know-how from top-level racing flows directly into the development of RCS racing clutches. State-of-the-art manufacturing methods, the highest quality standards and motorsport technologies make ZF Motorsport clutches the first choice for maximum performance and reliability - on circuits as well as in rallying, touring and endurance racing.

Applications

CIRCUIT / TOURING

Super GT, ELMS,

DTM, STCC, NLS, TCR, GT World Challenge etc.

FORMULA

Formula Ford,

Formula 3, Formula 4 etc. (RCS115/140)

RALLY

GT2 European Series,

WRC, ELMS, DRM, BRC, FRC etc.

Installation instructions:

As SACHS RCS clutches have not been developed specifically for a vehicle, but are vehicle-independent, the vehicle must be adapted to the clutch (see PDF documents above). The contour of the flywheel, the position, the travel and the shape of the release mechanism as well as the maximum available installation space must be checked and adapted if necessary.

Required information:

When ordering your SACHS RCS clutch, the required profile of the transmission input shaft must be specified. The different profiles offered are listed under „hub profile“. If you have any questions about the product, please do not hesitate to contact us via E-Mail or by telephone on +49 (0)40 / 3999 211.

Partners of ZF Race Engineering

English

English