Description

Manufacturer

Product Tags

Designed to make a

difference

ZF Race Engineering's SACHS motorsport clutches have stood for top-tier quality in international racing for decades. The ambition: continuous improvement and the drive to keep pushing the limits. From the lightest clutch used in Formula 1 to proven twin-plate and multi-plate systems in WRC, DTM, NASCAR, Le Mans and the Dakar Rally - ZF Motorsport technology is a core component of many winning cars worldwide.

SACHS Racing Clutch

Lamborghini Huracán GT3 / GT3 Evo

Sintered metallic 2.6 mm, triple-plate – vehicle-specific for Huracán GT3/Evo

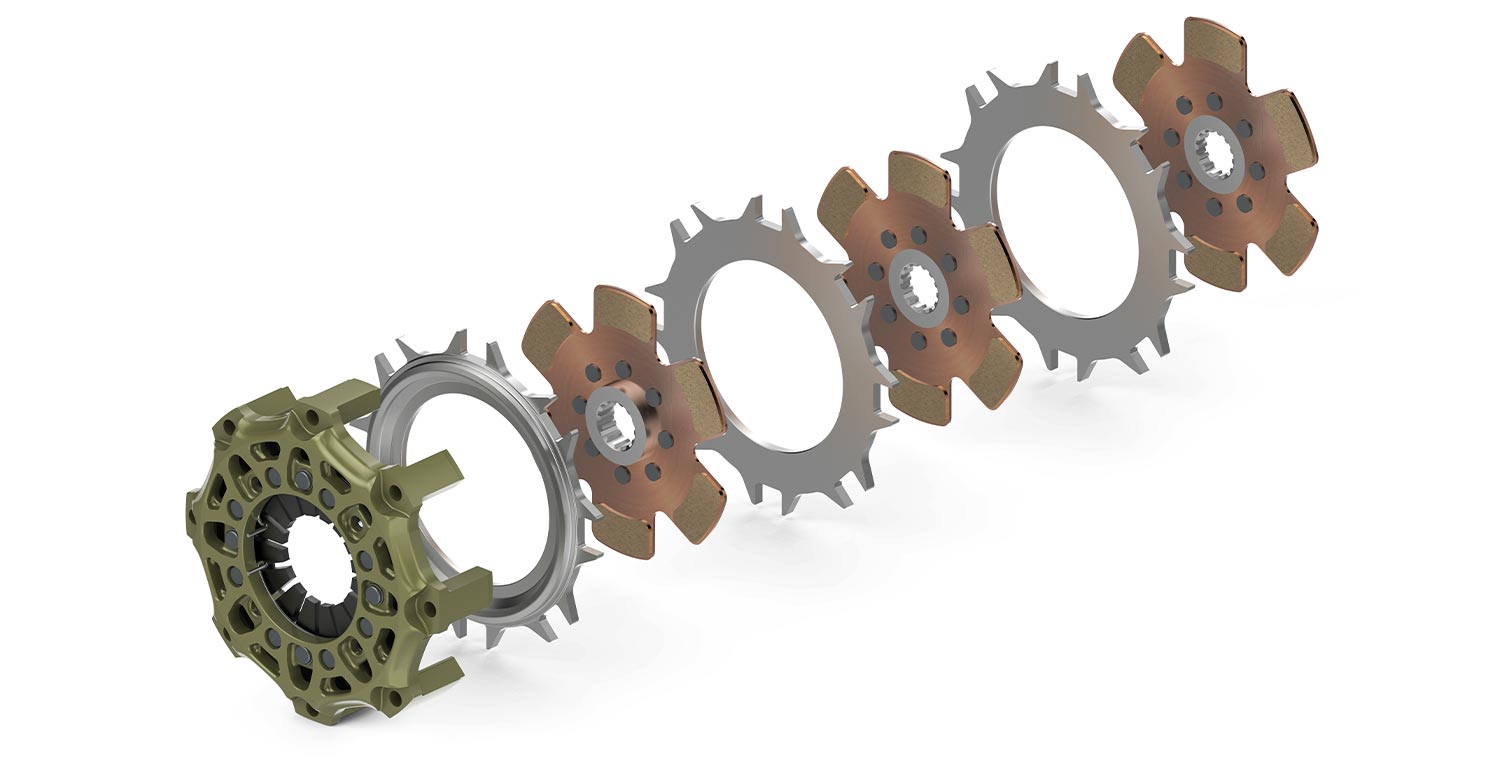

For Lamborghini Huracán GT3 (2015–2018) and Huracán GT3 Evo (from 2019): the SACHS RCS 3/140 S2.6 racing clutch is engineered for the V10 naturally aspirated drivetrain with a 6-speed sequential transaxle. The compact 140 mm diameter and low moment of inertia enable rapid rev-matching, short shift windows, and precise launch behavior.

The triple-plate layout distributes friction work across multiple contact surfaces, increasing torque density at a low overall height. The 2.6 mm sintered linings reduce rotating mass for maximum agility and repeatable engagement – ideal for standing starts, pit stop cycles, aggressive out-laps, and the high shift frequencies of modern GT3 calibrations.

Within the typical GT3 BoP output window of the 5.2 L V10 (> 500 hp, Evo nominally up to approx. 620 hp), the RCS 3/140 S2.6 delivers stable friction levels and high thermal robustness in the clutch system – matched to the engine characteristics and gear ratios of the Huracán powertrain.

Advantages

Light

low clutch height

Low mass and inertia

Less Mass

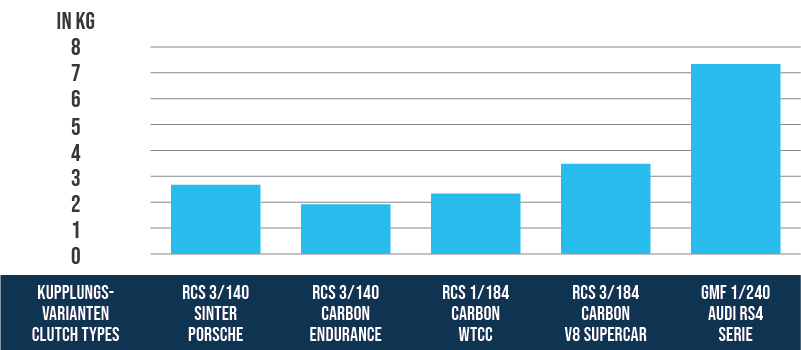

One of the greatest strengths of the RCS sintered clutch is its low mass and the associated low mass inertia.

The SACHS RCS clutches have been designed for racing with the objective that torque is transmitted rapidly and directly from the engine to the gearbox.

Reducing the weight of the crankshaft drive to lower the moment of inertia will considerably increase vehicle acceleration performance in the lower gears.

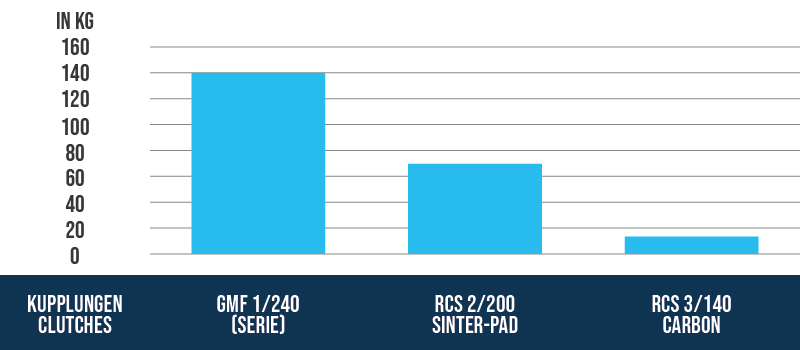

Faster Acceleration

If the clutch itself has a moment of inertia (MoI) of 0.061 kgm2, the MoI on the drive wheel will be 180 times higher (in first gear) for a reduction in transmission of 13.4:1 (13.42). If we convert this value into vehicle mass, we arrive around 145 kg of additional weight to be accelerated in first gear.

As a result of the low moment of inertia of the SACHS RCS clutch, shifting times are considerably reduced and the vehicle accelerates much faster.

The technology

Technical data RCS 3/140

-

Vehicle:

Lamborghini Huracán GT3 (2015-2018)

Lamborghini Huracán GT3 Evo (2019-2022) - Maximum engine torque [Nm]: 1,430

- Release diameter [mm]: 38

- Release force [N]: 4,200

- Release travel [mm]: 4.5 + 0.5

- Mass (weight) [kg]: 3.01

- Moment of inertia [kg·m²]: 0.009230

Clutch cover (housing)

Forged aluminum housing with high stiffness at low mass. The cover geometry promotes heat dissipation within the clutch system; the hard-wearing surface treatment reduces friction and fit wear – important for long service life with frequent starts and shifts.

Friction lining

Sintered metallic linings deliver high temperature capability and stable friction in dry high-load operation. 2.6 mm sintered linings minimize the rotating moment of inertia of the clutch pack – an advantage for instant throttle response, short shift times, and a clear pedal feel. Brief comparison: 5.2 mm = maximum thermal reserve/service life; 3.4 mm = balanced; 2.6 mm = highest agility for sprint and packaging-critical applications.

Hub spline profile

Supplied with the exact spline for the input shaft of the Huracán GT3/Evo transaxle. This ensures maximum fit accuracy, reliable torque transfer, and high durability in the drivetrain. Custom solutions are available on request.

Scope of supply

RCS 140 clutch cover (HA140), aluminum

1× RCS 140 pressure plate (PP140), steel

2× RCS 140 intermediate plate (IP140), steel

3× RCS 140 clutch disc, sintered 2.6

Hub length: short–medium–short

Quality Made in Germany

ZF Race Engineering has been among the technology leaders in motorsport for years. The combined know-how from top-level racing flows directly into the development of RCS racing clutches. State-of-the-art manufacturing methods, the highest quality standards and motorsport technologies make ZF Motorsport clutches the first choice for maximum performance and reliability - on circuits as well as in rallying, touring and endurance racing.

Applications

Europe

GT World Challenge Europe (Endurance & Sprint, formerly Blancpain),

24h Spa / Intercontinental GT Challenge, ADAC GT Masters, British GT,

Italian GT, DTM (GT3 era).

North America

IMSA WeatherTech (GTD & GTD PRO) incl. 24h Daytona, 12h Sebring, Petit Le Mans,

GT World Challenge America.

Asia / Pacific

GT World Challenge Asia, Asian Le Mans Series,

SUPER GT (GT300) – depending on homologation status / team setup.

Partners of ZF Race Engineering

English

English