Description

Manufacturer

Product Tags

Designed to make a

difference

ZF Race Engineering's SACHS motorsport clutches have stood for top-tier quality in international racing for decades. The ambition: continuous improvement and the drive to keep pushing the limits. From the lightest clutch used in Formula 1 to proven twin-plate and multi-plate systems in WRC, DTM, NASCAR, Le Mans and the Dakar Rally - ZF Motorsport technology is a core component of many winning cars worldwide.

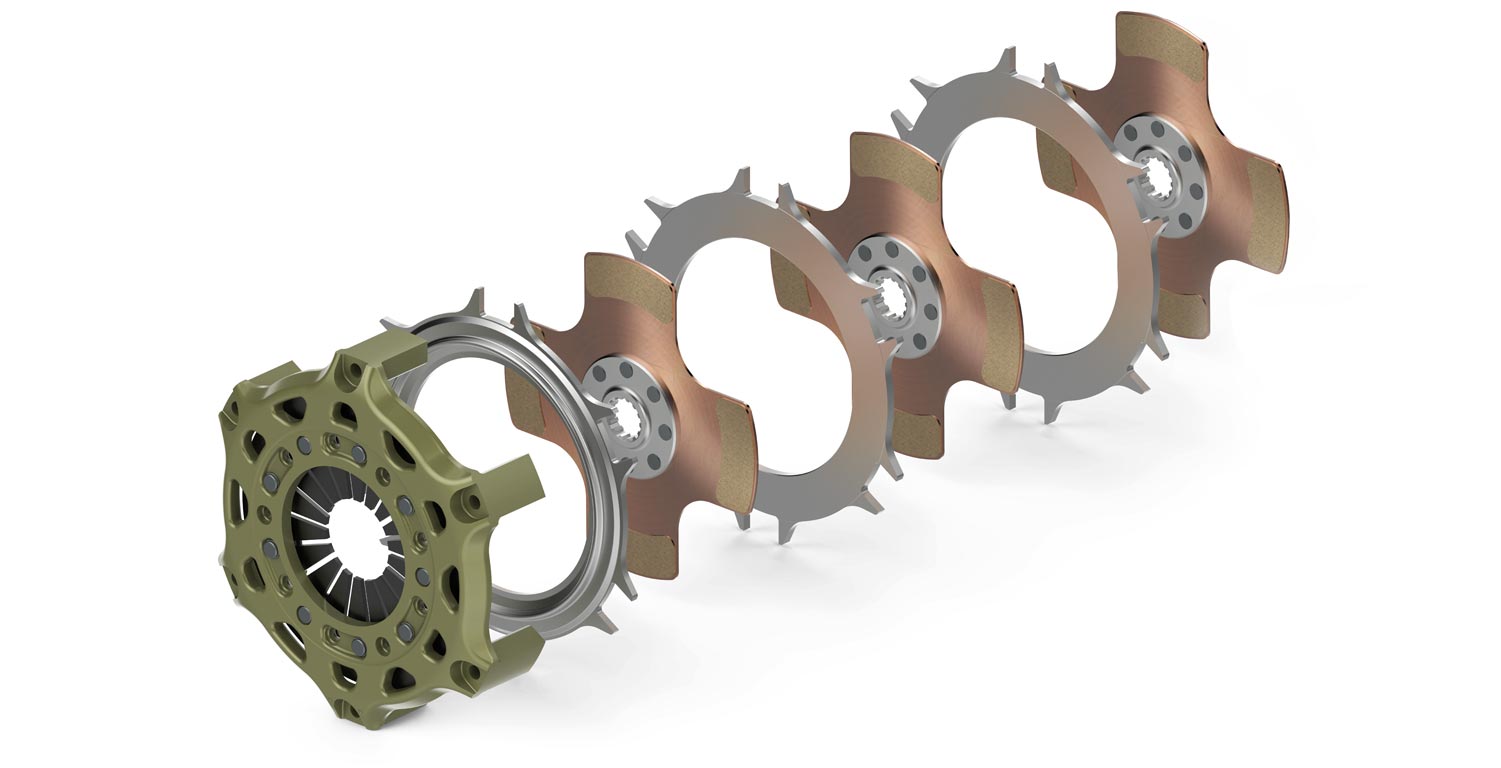

SACHS racing clutch

for Czinger 21C

Sintered metallic 2.6 mm, rigid design

Vehicle-specific for the road-legal Czinger 21C hypercar, limited to 80 units: the triple-disc SACHS RCS 3/184 racing clutch combines very high torque capacity with low rotating mass. Three friction discs significantly increase transmissible force at the same pressure plate load and friction level, while the low lining thickness enables direct response and short reaction times.

The sintered metallic friction material remains stable across the operating window of the 2.9-liter V8 hybrid powertrain (~1,250–1,350 hp) and ensures fast, clearly defined engagement. The 2.6 mm configuration lowers moment of inertia – the engine revs more freely, and the bite point stays precise and repeatable. At the same time, the three-disc layout distributes friction work across multiple interfaces, reducing specific surface pressure and smoothing temperature peaks.

This specification handles up to 1,154 Nm maximum engine torque. Together with the forged aluminum clutch cover (housing) and high-strength steel pressure and intermediate plates, it forms a durable, repeatable system – ideal for record runs, time-attack, and exclusive track events.

Advantages

Light

low clutch height

Low mass and inertia

Less Mass

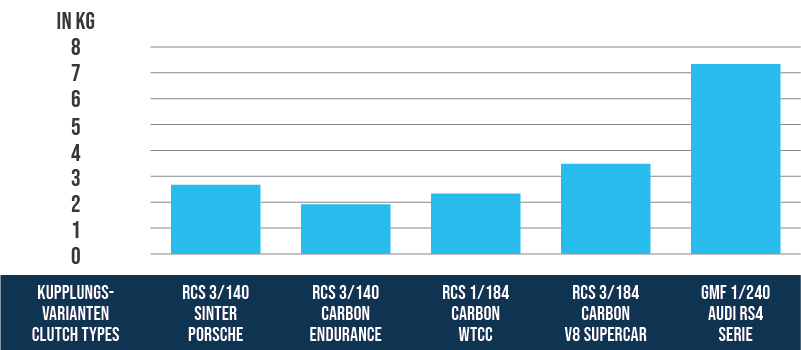

One of the greatest strengths of the RCS sintered clutch is its low mass and the associated low mass inertia.

The SACHS RCS clutches have been designed for racing with the objective that torque is transmitted rapidly and directly from the engine to the gearbox.

Reducing the weight of the crankshaft drive to lower the moment of inertia will considerably increase vehicle acceleration performance in the lower gears.

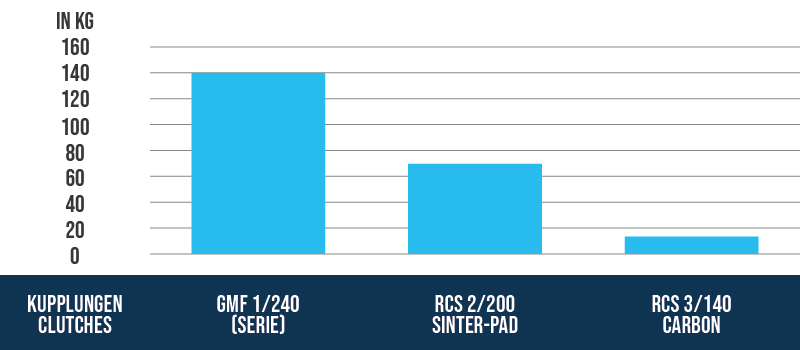

Faster Acceleration

If the clutch itself has a moment of inertia (MoI) of 0.061 kgm2, the MoI on the drive wheel will be 180 times higher (in first gear) for a reduction in transmission of 13.4:1 (13.42). If we convert this value into vehicle mass, we arrive around 145 kg of additional weight to be accelerated in first gear.

As a result of the low moment of inertia of the SACHS RCS clutch, shifting times are considerably reduced and the vehicle accelerates much faster.

Technology

Technical data RCS 3/184:

- Vehicle:

Czinger 21C V8 2.9L twin-turbo - maximum engine torque [Nm] : 1,154

- release diameter [mm] : 49

- release force [N] : 2,400

- release travel [mm] : 5.0 +0.5

- mass (weight) [kg] : 4.06

- moment of inertia [kg·m²] : 0.022262

Clutch cover (housing)

The SACHS RCS 184 clutch cover is made from high-strength forged aluminum and engineered for maximum stiffness with minimal weight. The housing geometry supports efficient heat dissipation and stabilizes the clutch pack temperature window – matched to the 21C's thermal demands.

An extremely wear-resistant patented hard coating reduces sliding and fit wear, protects against corrosion, and delivers long service life – even in repeated launch and pit stop sequences.

Friction lining

Sintered metallic linings in 2.6 mm, applied onto the carrier disc, reduce part count and mass, increase stiffness of the friction pair, and minimize compressibility. Result: very precise bite point, short response times, and crisp engagement. Direct heat flow into the carrier promotes fast temperature stabilization – crucial for time-attack and record attempts.

Hub spline profile

This RCS 3/184 S2.6 is supplied with the exact matching hub spline profile for the Czinger 21C V8 hypercar, precisely matched to its gearbox input shaft. This guarantees maximum fit, dependable torque transfer, and durability in high-performance use. Different hub lengths are available for optimal packaging; standard (unless otherwise specified): long–medium–long.

Scope of supply

RCS 184 clutch cover (HA184), aluminum

1x RCS 184 pressure plate (PP184), steel

2x RCS 184 intermediate plate (IP184), steel

3x RCS 184 clutch disc, sintered metallic 2.6

hub length: long–medium–long

Quality Made in Germany

ZF Race Engineering has been among the technology leaders in motorsport for years. The combined know-how from top-level racing flows directly into the development of RCS racing clutches. State-of-the-art manufacturing methods, the highest quality standards and motorsport technologies make ZF Motorsport clutches the first choice for maximum performance and reliability - on circuits as well as in rallying, touring and endurance racing.

Applications

Time-attack and records

Laguna Seca, Circuit of the Americas (COTA),

Goodwood Hillclimb and other record and hot-lap formats.

Exclusive track events

Private track days, manufacturer and VIP events,

demonstration runs and media sessions.

Partners of ZF Race Engineering

English

English