Designed to make a

difference

ZF Race Engineering's SACHS motorsport clutches have stood for top-tier quality in international racing for decades. The ambition: continuous improvement and the drive to keep pushing the limits. From the lightest clutch used in Formula 1 to proven twin-plate and multi-plate systems in WRC, DTM, NASCAR, Le Mans and the Dakar Rally - ZF Motorsport technology is a core component of many winning cars worldwide.

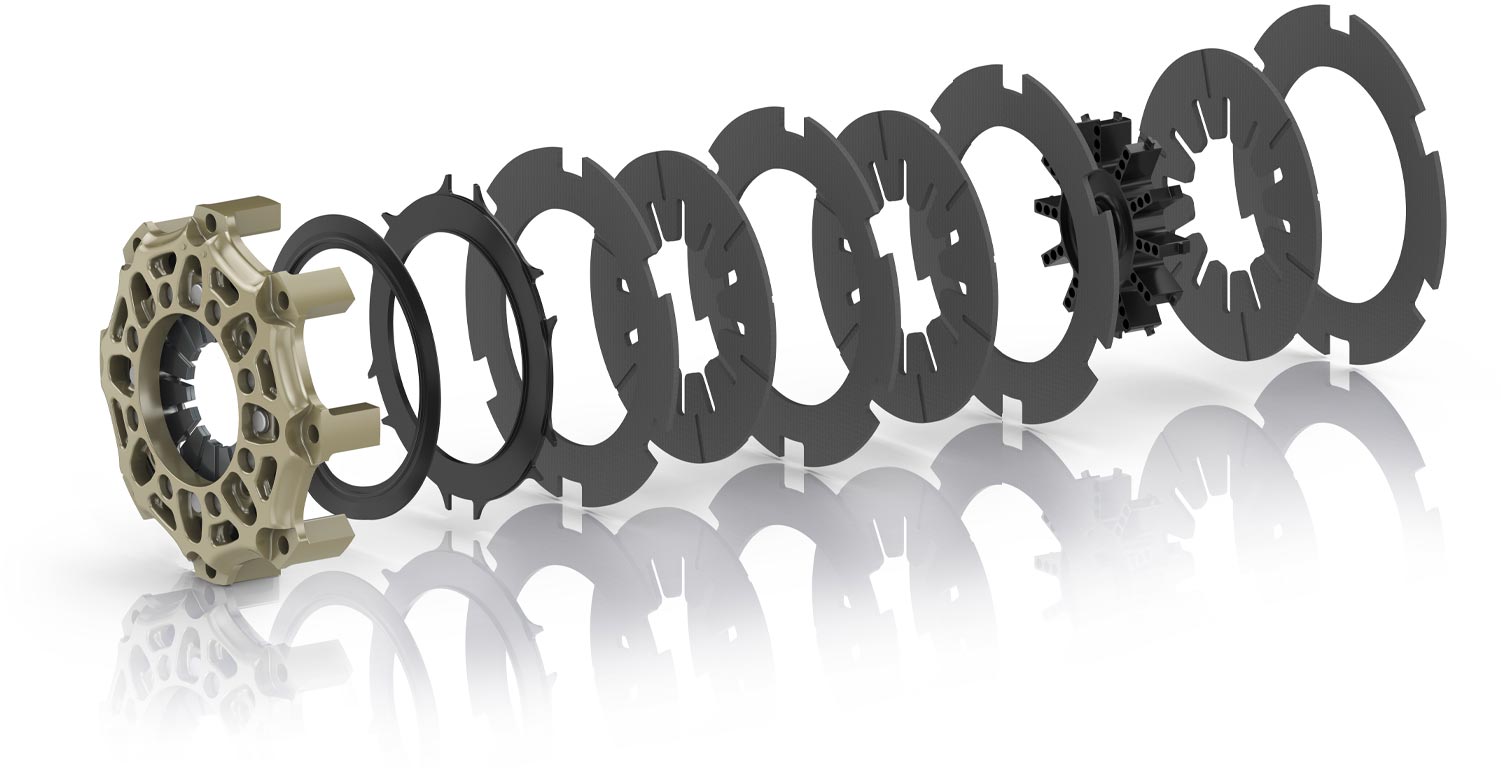

SACHS carbon racing clutch

Ferrari 458 GT2 / GTLM

The Clutch of Competence

Vehicle-specific for the Ferrari 458 GT2 / GTLM (2011–2015): the three-disc SACHS RCC 3/140 carbon racing clutch delivers maximum circuit performance with a minimal diameter and the lowest moment of inertia - ideal for LM GTE/GT2 regulations, tight pit stop cycles, and the high-rev character of the 4.5 L V8.

ZF Race Engineering transfers top technology from Formula 1, Super GT, and WRC into the GT2/GTE application. Focus: low weight, lowest inertia, and high temperature resistance - for consistent, repeatable performance over long stints in WEC/ELMS as well as ALMS/IMSA GTLM.

The RCC 3/140 meets the stringent demands of the 458 GT2 / 458 GTE / 458 GTLM: precise response at launch and during shifts, stable friction levels in high-temperature windows, and strong reserves for endurance use.

A system mass of just 2.17 kg and a low moment of inertia of 0.00687 kg·m² support rapid rev matching and short shift windows. In this specification, up to 1,000 Nm can be transmitted - a perfect match for the torque profile of the naturally aspirated 4.5 L V8 in the 458 GT2/GTLM.

Benefits

maximum thermal resilience - carbon quality from Formula 1

very low weight and minimal moment of inertia

smooth and comfortable launch behavior

no flywheel wear

extreme durability - up to 4x longer than conventional sintered racing clutches

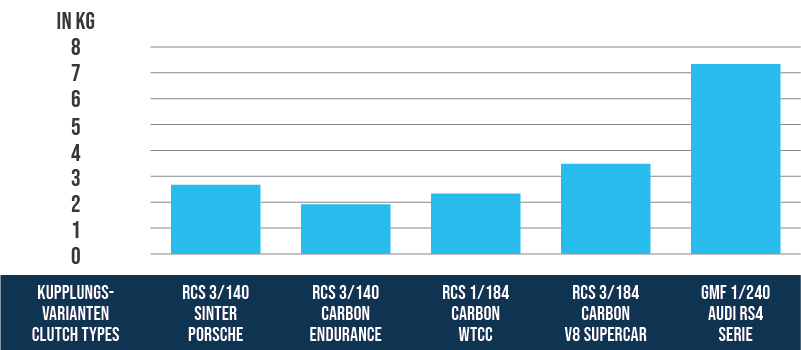

Lowest mass

One of the major strengths of a carbon racing clutch is its low mass and the resulting low moment of inertia.

They are designed for the lowest possible mass with the goal of transferring engine torque to the gearbox as quickly and directly as possible.

Lightening measures in the cranktrain that reduce the moment of inertia increase vehicle acceleration noticeably in the lower gears.

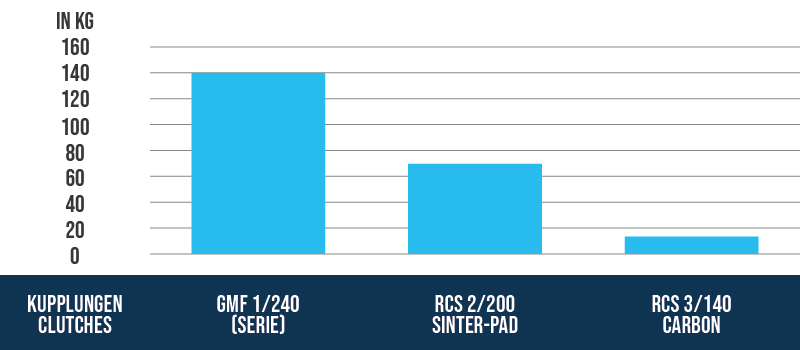

Faster acceleration

If, for example, the clutch has a moment of inertia (Mtm) of 0,061 kgm2, with a gearbox ratio of 13,4:1 (first gear ratio) this acts at the drive wheel with 180 times the value (13,42). Converting Mtm into vehicle mass results in an additional weight of approx. 145 kg in 1st gear that must be accelerated.

Thanks to the extremely low inertia of the SACHS carbon clutch, shift times are significantly reduced and the vehicle accelerates faster.

Maximum service life

For carbon clutches there are pressure plate and shim packs available that compensate carbon wear. With these compensation pressure plates the clutch can be reset to as-new condition - significantly extending service life.

Each unit undergoes stringent quality checks and is individually tested and measured before shipment. Preload force, installation height and release characteristics are documented. The preinstalled carbon stack thickness is also recorded - the included document supports maintenance and the shimming process (compensation pressure plates for refurbishment).

Technology

Technical data RCC 3/140

- Vehicle:

Ferrari 458 GT2 4.5 L V8 (2011–2015)

Ferrari GTE/LM Pro/Am (2011–2015) - maximum engine torque [Nm] : 950

- release diameter [mm] : 38

- release force [N] : 4,800

- release travel [mm] : 4.5 + 0.5

- mass (weight) [kg] : 2.17

- moment of inertia [kg·m²] : 0.00687

Clutch cover (housing)

High-strength forged aluminum engineered for maximum stiffness at minimum weight. The housing geometry supports efficient heat dissipation and stabilizes the clutch pack temperature window - tailored to the thermal loads of GTE endurance running (WEC/ELMS, Sebring, Le Mans).

Material: carbon

Carbon excels in endurance with high temperature resistance, consistent friction across a wide operating window, and finely metered response even at elevated disc temperatures. Its low density reduces inertia and drag torque; good thermal conductivity promotes rapid temperature stabilization - advantages in sprints, tight circuits, and 24 h events.

Hub spline profile

Vehicle-specific hub spline profile: the RCC 3/140 is supplied with the correct hub spline for the Ferrari 458 GT2 / GTLM - precisely matched to this model's gearbox input shaft. This ensures maximum fit accuracy, reliable power transfer, and durability in competition. Custom solutions are available on request.

Scope of supply

RCS 140Y clutch cover (HA140), aluminum

3 × RCS 140Y carbon driven plates

4 × RCS 140Y carbon pressure plates

1 × RCS 140Y hub, steel

1 × RCS 140Y base plate, steel

1 × RCS 140Y pressure ring, steel

Quality Made in Germany

ZF Race Engineering has been among the technology leaders in motorsport for years. The combined know-how from top-tier racing flows directly into the development of carbon racing clutches. State-of-the-art manufacturing methods, the highest quality standards and motorsport technologies make carbon clutches the first choice for maximum performance and reliability - on circuit racing as well as in rally, formula and endurance applications.

Applications

Europe

ILMC, WEC (GTE-Pro/Am), ELMS (GTE),

24h Le Mans, International GT Open (GT2 specification).

North America

ALMS (GT), IMSA/TUDOR (GTLM),

wins including 12h Sebring & Petit Le Mans during the period of use.

Asia/Pacific

Asian Le Mans Series (GTE),

WEC rounds Fuji & Shanghai (GTE-Pro/Am).

Partners of ZF Race Engineering

English

English