Designed to make a

difference

ZF Race Engineering's SACHS motorsport clutches have stood for top-tier quality in international racing for decades. The ambition: continuous improvement and the drive to keep pushing the limits. From the lightest clutch used in Formula 1 to proven twin-plate and multi-plate systems in WRC, DTM, NASCAR, Le Mans and the Dakar Rally - ZF Motorsport technology is a core component of many winning cars worldwide.

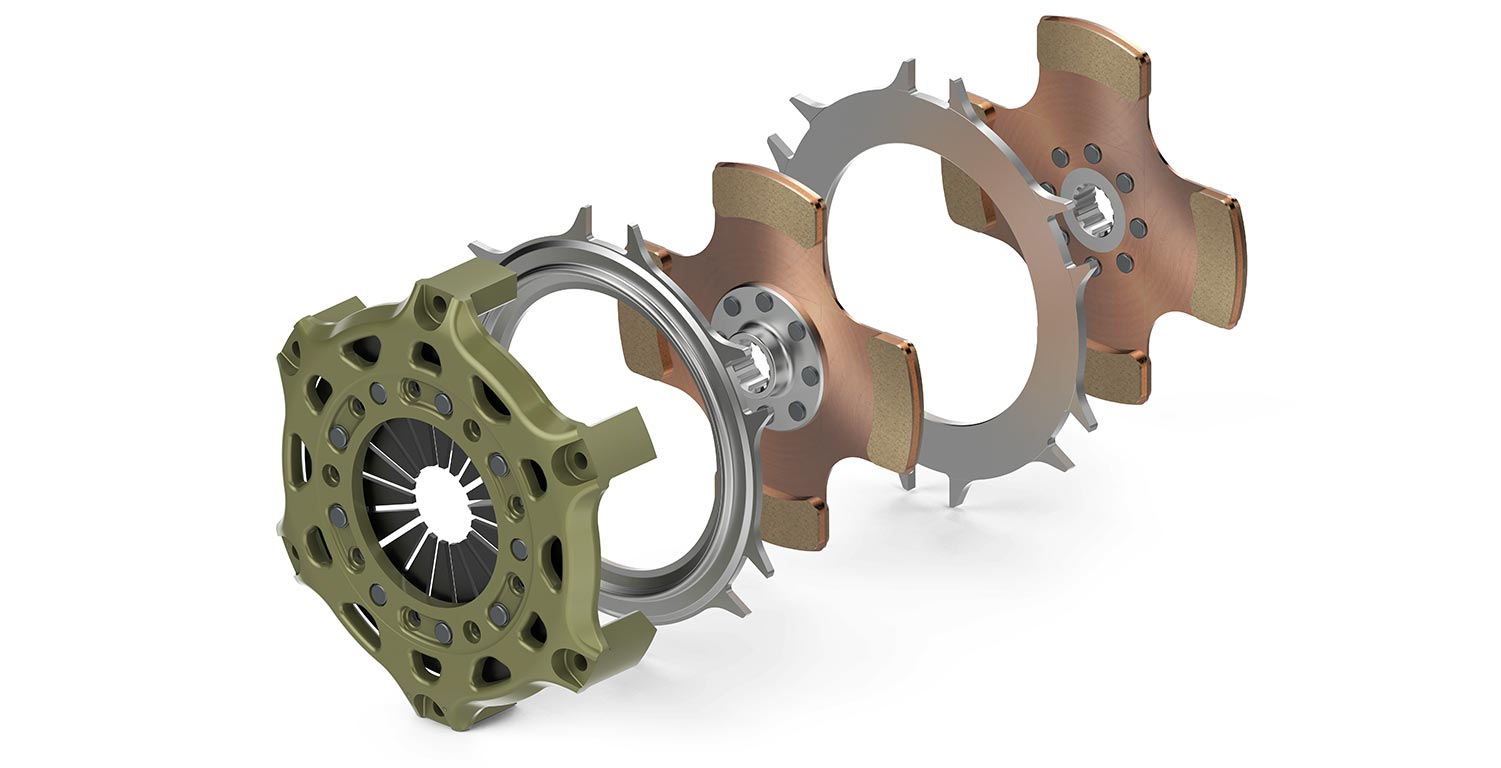

SACHS racing clutch module

BMW M3 E36

Twin-disc 7.8 mm sintered metallic racing clutch with lightweight single-mass flywheel for BMW M3 E36

This vehicle-specific SACHS RCS 2/184 racing clutch module is engineered for the BMW M3 E36 (model years 1992-1999). The module combines a twin-disc SACHS RCS 2/184 S7.8 racing clutch with a lightweight single-mass flywheel and a matching release bearing. Total system mass is just 7.50 kg versus approx. 19.3 kg for the OE clutch - a weight saving of around 61 %. The significantly lower rotating mass improves engine pick-up, sharpens throttle response, and reduces driveline load - ideal for track tools, club racing, and competition cars based on the BMW M3 E36.

The twin-disc SACHS RCS 2/184 racing clutch from ZF Motorsport delivers high endurance capability, precise modulation, and consistent lap times. The 184 mm diameter offers the optimal balance of compact package, low rotating mass, and sufficient friction area for stable temperatures. In combination with 7.8 mm sintered metallic pads you gain a large wear reserve and an effective thermal buffer - the bite point remains precise over many race starts and long stints, temperature spikes are smoothed, and engagement stays finely controllable. The sintered metallic linings provide reliable grip and fade resistance at elevated disc temperatures, increase torque capacity, and extend service intervals. This specification transmits up to 1,308 Nm maximum engine torque - with ample headroom for uprated M3 engines.

The forged aluminum clutch cover (housing) combines low mass with high stiffness and a clean thermal balance - ideal for endurance, rally, and demanding track day setups. Pressure and intermediate plates are supplied exclusively in high-strength steel. Compared to cast components, steel withstands mechanical and thermal peaks far better and is fully launch-proof - perfect for standing starts and repeated maximum loads in the BMW M3 E36.

Advantages

High wear volume

High temperature resistance

Long operational life

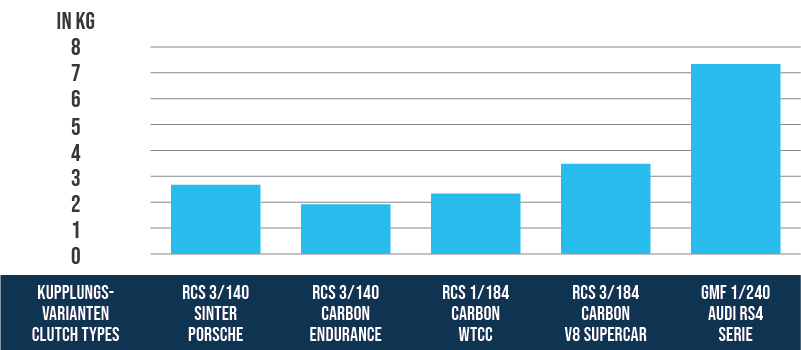

Less Mass

One of the greatest strengths of the RCS sintered clutch is its low mass and the associated low mass inertia.

The SACHS RCS clutches have been designed for racing with the objective that torque is transmitted rapidly and directly from the engine to the gearbox.

Reducing the weight of the crankshaft drive to lower the moment of inertia will considerably increase vehicle acceleration performance in the lower gears.

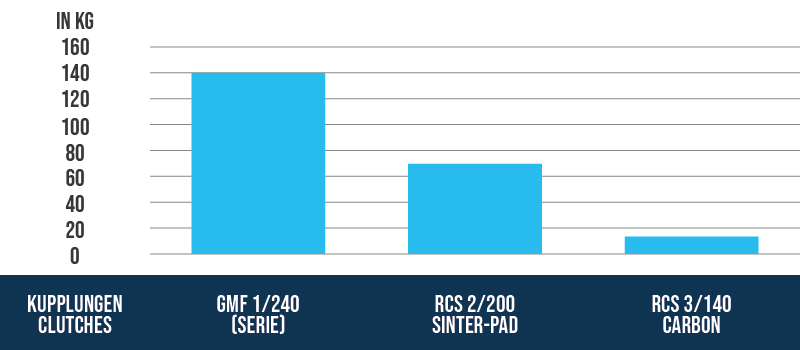

Faster Acceleration

If the clutch itself has a moment of inertia (MoI) of 0.061 kgm2, the MoI on the drive wheel will be 180 times higher (in first gear) for a reduction in transmission of 13.4:1 (13.42). If we convert this value into vehicle mass, we arrive around 145 kg of additional weight to be accelerated in first gear.

As a result of the low moment of inertia of the SACHS RCS clutch, shifting times are considerably reduced and the vehicle accelerates much faster.

Technology

Technical data RCS 2/184:

- Vehicle:

BMW M3 E36 (1992-1999) - maximum engine torque [Nm] : 1,310

- release diameter [mm] : 49

- release force [N] : 4,300

- release travel [mm] : 5.0 +0.5

- mass (weight) clutch pack [kg] : 3.49

- moment of inertia clutch pack [kg·m²] : 0.019852

- total module mass [kg] : 7.50

- weight saving vs OE : approx. 61 %

Clutch cover (housing)

The BMW M3 E36 module uses the SACHS RCS 184 clutch cover from ZF Motorsport. It is manufactured from high-strength forged aluminum and designed for maximum stiffness with minimal weight. The specific housing geometry promotes efficient heat dissipation and stabilizes the clutch pack's temperature window - a clear advantage for high-revving naturally aspirated or turbo conversions.

A key feature is the extremely wear-resistant, patented aluminum hard coating. This full-surface treatment reduces sliding and fit wear, protects against corrosion, and delivers long service life - even under frequent load changes and intensive track day use with the M3 E36.

Friction lining - sintered metallic

The SACHS RCS 2/184 clutch discs use sintered metallic friction material with 7.8 mm lining thickness. The increased thickness enlarges the wear reserve and thermal capacity of the friction system. This reduces local temperature peaks, lowers the risk of thermal instability (fading, hot spots, distortion), and keeps the friction level stable over extended duty cycles.

Sintered metallic friction delivers a very direct response: hard launches, fast and well-defined engagement at race start, and consistent shifts even at high disc temperatures - ideal for powerful BMW M3 E36 cars on semi-slicks or slicks.

Scope of supply

1x RCS 184 clutch cover (HA184), aluminum

1x RCS 184 single-mass flywheel, steel

1x RCS 184 pressure plate (PP184), steel

1x RCS 184 intermediate plate (IP184), steel

2x RCS 184 clutch disc, sintered metallic pad 7.8 mm

1x clutch release bearing

Quality Made in Germany

ZF Race Engineering has been among the technology leaders in motorsport for years. The combined know-how from top-level racing flows directly into the development of RCS racing clutches. State-of-the-art manufacturing methods, the highest quality standards and motorsport technologies make ZF Motorsport clutches the first choice for maximum performance and reliability - on circuits as well as in rallying, touring and endurance racing.

Applications

EUROPE

Track days and club racing,

NATC, BMW Challenge, Classic Masters, NLS etc.

NORTH AMERICA

NASA Spec3 (E36 / E46)

Spec and club racing (NASA, BMW CCA, SCCA etc).

Partners of ZF Race Engineering

Description

Manufacturer