Stress tests on the flywheel.

Possible damages may caused by a faulty clutch but also by the engine.

If defects are suspected in the dual-mass flywheel ("DMF" for short) the cause study begins. If the fault diagnostics options are not sufficient for the installed DMF, the DMF can also be examined visually, mechanically, or on a test bench, although this latter possibility remains a task for the manufacturer.

Any workshop can check a dismantled dual-mass flywheel with simple tools. It is important to know the right methods.

Flywheel telltale signs

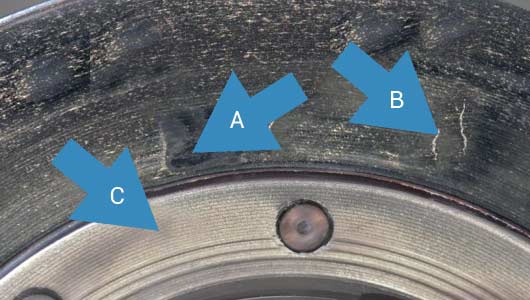

During a visual inspection, a discolored friction surface on the secondary flywheel (arrow A) indicates an overheated or overloaded DMF. This effect can occur if drivers let the clutch slip for too long. In addition, there is a danger that longer-lasting overheating will harden the special lubricant in the DMF, which frequently ends in component failure.

If there are visible fissures in the friction surface (arrow B), the DMF has to be replaced – otherwise it may crack. Yellowish discolorations in the area below the friction surface (arrow C) are also a reason for replacement, as the DMF axial bearing is then worn. This is audible during vehicle operation. If lubricant with fragments escapes from the inside of the component, a new part also has to be fitted.

Rotate to the maximum extent

For the lever or mobility test, the primary flywheel has to be fixed in a vise – with two bolts through the holes for the crankshaft mounting. A test lever then has to be screwed to the holes for the clutch mounting. If the secondary flywheel is rotated from the loose position to the left and right maximum stop, the angles achieved and the expenditure of force felt in both directions should be identical. In addition, no exceptional movement resistance may occur.

If these criteria are not met, this indicates defective or broken components inside the DMF. These may scratch through the housing so that lubricant escapes. If the full rotation angle of around 60 degrees is not reached on each side, there is also a possibility of the lubricant hardening as a result of thermal overloading – this is often visible from the discolorations. In these cases, the DMF has to be replaced.

English

English