Racing Clutch SACHS RCS - Advantages

Comparison standard and racing clutch

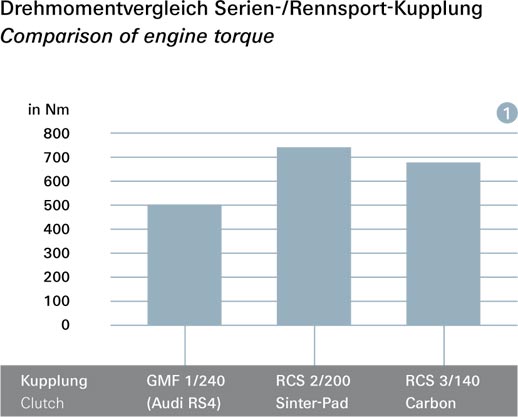

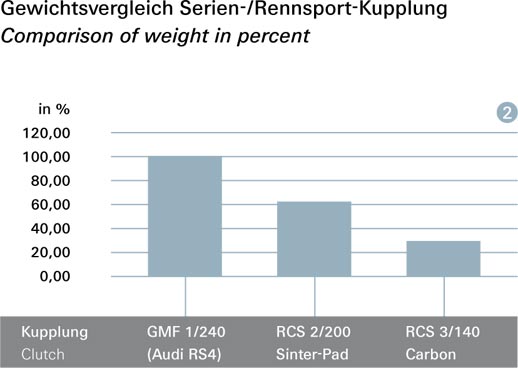

The following example shows the influence of clutch diameter on certain parameters. It compares a standard GMF 1/240 (Audi RS4) clutch with a RCS 2/200 sinter pad and a RCS 3/140 carbon clutch.

The RCS 2/200 sinter pad clutch already shows considerable advantages over the standard GMF 1/240 ( Diagram 1 ).

The RCS 2/200 sinter pad clutch already shows considerable advantages over the standard GMF 1/240 ( 1 ). It has 40 % less weight ( 2 ), and the MoI is 50% lower.

The RCS 3/140 carbon clutch is around 70 % lighter ( 2 ) and its MoI is approx. 90 % lower than the standard unit.

This illustrates the major role the clutch diameter plays in reducing weight when a racing clutch is used instead of a standard clutch.

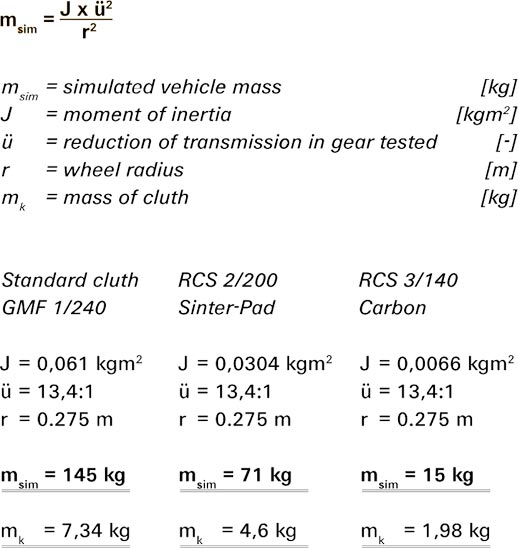

Conversion of clutch weight into simulated vehicle weight

At first glance, one might think that the mass of a clutch (5-10 kg) is negligible in comparison to the mass of the vehicle to be accelerated (ca. 1000 kg). What is often overlooked here, however, is the reduction of transmission.

If the clutch itself has a moment of inertia (MoI) of 0.061 kgm2, the MoI on the drive wheel will be 180 times higher (in first gear) for a reduction in transmission of 13.4:1 (13.42). If we convert this value into vehicle mass, we arrive around 145 kg of additional weight to be accelerated in first gear. This inertia effect declines as the gear ratio decreases.

Reducing the weight of the crankshaft drive to lower the moment of inertia will considerably increase vehicle acceleration performance in the lower gears.

English

English