Clutch Diagnostics and Troubleshooting

Tips for the proper handling of clutches.

Installing clutches

How to install a clutch kit

If you observe only a few decisive details during clutch replacement, you can mostly save a lot of time and high costs and avoid unhappy customers.

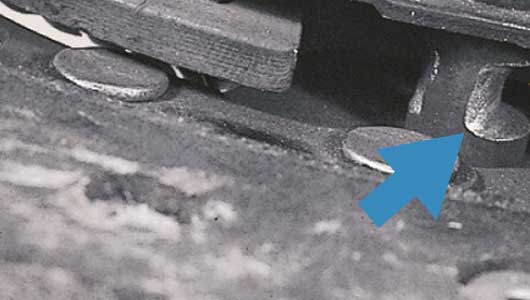

Check clutch disks

Greasing the hub spline of clutch disks

Clutch noise

Clutch grabs

Clutch slips

Clutch does not disengage

Checking DMF

English

English